Our Planet

In 2022, we conducted a comprehensive analysis of our CO2 emissions, focusing on scope 1 and scope 2 emissions primarily from quarrying and manufacturing. We report scope 3 emissions separately, emphasizing our commitment to environmental responsibility.

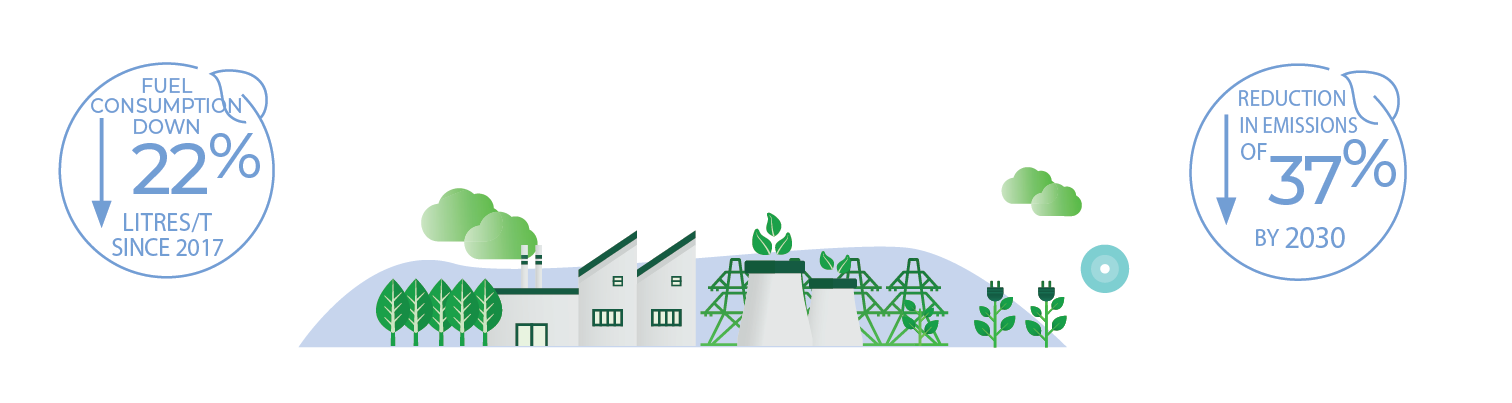

Since 2019, we’ve been actively monitoring and striving for a 37% reduction in scope 1 and scope 2 emissions, maintaining a 90:10 split. The complexity of scope 3 emissions requires collaboration with supply chain partners, and we’re working diligently on addressing them.

Our dedication to environmental management dates back to 2014, with the ISO 50001 certification for energy management, allowing us to use data-driven insights to effectively reduce carbon emissions. We also uphold ISO 14001 certification to support environmental protection and adapt to changing conditions.

Introducing Euro 6D Trucks controlled by our Motion Metrics system and providing Eco-Driver training has resulted in a commendable 22% reduction in fleet fuel consumption per tonne. Embracing LPG dryers, low-energy heat, and ‘warm mix’ technology has significantly cut our CO2 emissions.

Investing in recycled asphalt manufacturing has enabled us to reduce raw material extraction and lower embodied CO2 by 15%. Our goal is to make all asphalt facilities RAP-enabled by Q3 2023.

Our waste management practices are stringent, emphasizing strict segregation to achieve a minimum 80% recycling rate and avoid landfill, with active membership in Repak. We’ve also taken steps to minimize timber pallets in our supply chain.

In line with our commitment to a circular economy, we repurpose process waste into high-quality recycled concrete aggregate (RCA), replacing up to 12% of aggregate in paving products. Our crushing and repurposing machinery ensures 100% recycling of concrete paving units into RCA for reuse.

Biodiversity and Planning

When it comes to biodiversity and planning, our ISO 14001 Environmental Management Systems play a crucial role in ensuring that our quarrying activities enhance and protect biodiversity. Quarry faces provide valuable breeding and feeding sites for species like Peregrine Falcons, Sand Martins, solitary bees, and hunting wasps. Additionally, water bodies created during operations or restoration efforts serve as vital habitats for various aquatic life forms.

We collaborate closely with the National Parks and Wildlife Service (NPWS) to monitor and protect Peregrine Falcons and strictly adhere to guidelines for biodiversity conservation within the extractive industry.

Environmental impact mitigation remains a top priority for us, with our robust Environmental Management System (EMS) guiding our efforts. We continually monitor emissions to minimize our quarry’s impact on the environment. Planning consents also include emission limit values for dust, noise, blasting, and groundwater, ensuring we meet stringent environmental standards.

We diligently collect and report environmental data from our quarries and pits, covering various aspects such as dust deposition, noise levels, and groundwater. This data helps us make informed decisions and maintain our commitment to environmental responsibility.